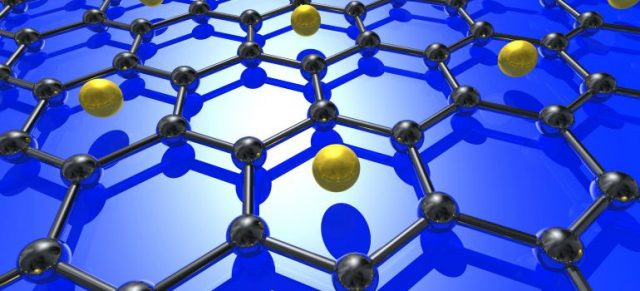

Nanoimprint lithography (NIL) has emerged as a powerful nanofabrication technique that enables the creation of intricate patterns and structures at the nanoscale. This article explores the principles, applications, advantages, and challenges associated with nanoimprint lithography. From its inception to its current state, NIL has demonstrated great potential in various fields, including electronics, photonics, and biomedical engineering. This article aims to shed light on the significance of this technique and its role in shaping the future of nanofabrication.

Overview of lithography techniques, including photolithography and electron beam lithography, comparison of traditional lithography techniques to nanoimprint lithography. Detailed explanation of the steps involved in nanoimprint lithography, including template fabrication, material deposition, and imprinting, Discussion of the different imprinting methods: thermal, UV, and soft imprinting

Overview of the materials employed in NIL, including resist materials, templates, and release agents, considerations for material selection based on the desired pattern and application. Utilizing NIL for the fabrication of nanoscale electronic devices, such as transistors and memory storage, Enhancing performance and reducing the cost of semiconductor manufacturing. Creating nanoscale optical structures, such as diffraction gratings, waveguides, and photonic crystals, enabling advancements in high-speed optical communication and integrated photonics. Facilitating the fabrication of microfluidic devices, biosensors, and drug delivery systems, Enhancing the precision and functionality of medical devices and diagnostics

Harnessing nanoimprint lithography for the development of efficient solar cells and energy storage devices, Advancing technologies for sustainable energy generation and environmental monitoring. High resolution and pattern fidelity at the nanoscale, cost-effectiveness compared to traditional lithography techniques, compatibility with various materials and substrates. Template fabrication and maintenance issues, Control of defects and uniformity across large areas, scaling up to mass production

Exploring hybrid approaches, combining nanoimprint lithography with other nanofabrication methods, Development of new imprint materials and processes for enhanced performance and versatility. Investigating the potential for continuous and high-throughput nanofabrication using roll-to-roll NIL, Applications in flexible electronics and large-area manufacturing. Integrating nanoimprint lithography with additive manufacturing techniques for complex 3D nanostructures, Pushing the boundaries of nanofabrication and enabling new functionalities

Nanoimprint lithography has revolutionized nanofabrication by enabling the creation of intricate patterns and structures at the nanoscale. With its wide range of applications and numerous advantages, NIL holds tremendous potential for advancements in various industries. While challenges remain, ongoing research and innovation in template fabrication, defect control, and scalability are paving the way for the future of nanoimprint lithography. As we continue to explore new possibilities, NIL is poised to shape the landscape of nanofabrication and drive progress in fields ranging from electronics to biomedicine.